ThermaTrace has developed an enviable reputation and became a leader in completing front-end, detail engineering, procurement, fabrication and installation of heat tracing systems.

ThermaTrace managing partners manage team of highly skilled engineers and designers, providing innovative and superior solutions on Heat Tracing.

ThermaTrace can offer to the client considerable savings using proven methods on previous projects, since typical refinery usually has approx. 1 million feet of traced piping.

Heat tracing shall be specified for:

The following guidelines shall be used in the specification of heat tracing:

Winterization, with heat tracing is applied to systems in accordance with the guidelines set out below. Where fitted to a water based system, the tracing temperature will be 10 °C (freeze protection). Tracing temperature for other systems shall be specified in the line list. In general, winterization will not be required for areas which are enclosed and therefore not subject to external ambient conditions.

Basic protection

Protective Heating

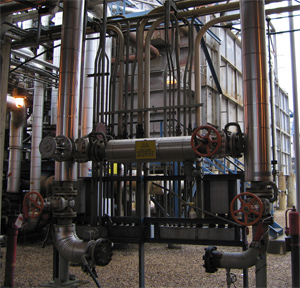

This method of winterization involves the addition of heat to piping, equipment and instruments to compensate for heat loss to the environment. To minimize heat loss to environment, insulation is provided. Heat is supplied by providing tracing or jacketing for piping, instruments and some equipment, and internal coils for vessels and tanks.

These methods include operating techniques and insulation. All types of winterization may be incorporated during detail design, keeping in mind operability and economics.

Typical piping that is almost always heat traced for winterizing, either to prevent piping damage, equipment damage, and operating problems, include:

To winterize instruments, the following need to be considered:

Safety showers are required at location in a plant where there is a possibility of an operator getting sprayed by toxin, caustic, acid or otherwise harmful material.

For personal safety, the water in the shower system should be maintained as closely as possible to 21 °C and should never exceed 35 °C.

The shower system should be externally insulted to serve the dual purpose of freeze protection and protection of overheating due to solar radiation. Heat tracing shall be used with a thermostat to ensure that water temperature remains relatively constant.

During cold weather, condensation can occur in compressor suction lines, particularly if the compressor is shut down for a few minutes. This can be avoided by tracing the suction line. The suction line in a centrifugal compressor is not critical but is generally traced in cold climates.

Consideration should also be given to:

For pump winterization the following equipment components need to be considered:

Pumps and drivers may also be winterized by being enclosed or partially enclosed in a suitable housing. Normally only pumps operating above 204 °C are insulated, but they may require insulation or enclosed in cage for personnel protection.

Air or gas receivers, water separations or dryers which collects moisture may have internal steam coils, be heat traced or steam jacketed, and insulated if not situated in a heated building.

Condensate flash drums, blow-down drums, and de-super heaters which are usually located outdoors may also be heat traced and insulated.

Winterization of vessels may be up to the normal liquid level or high liquid level or interface level only. Water boots are completely heat traced and insulated.

Bottoms of fuel gas knockout drums, gas scrubbers, flare drums and low points in above ground gas lines, (subject to freezing) should be heat traced and insulated.

Generally, most vessels and columns are already insulated for heat conservation, and in some application heat traced or jacketed, it temperature control is needed for process stability. This handles the winterization problem.